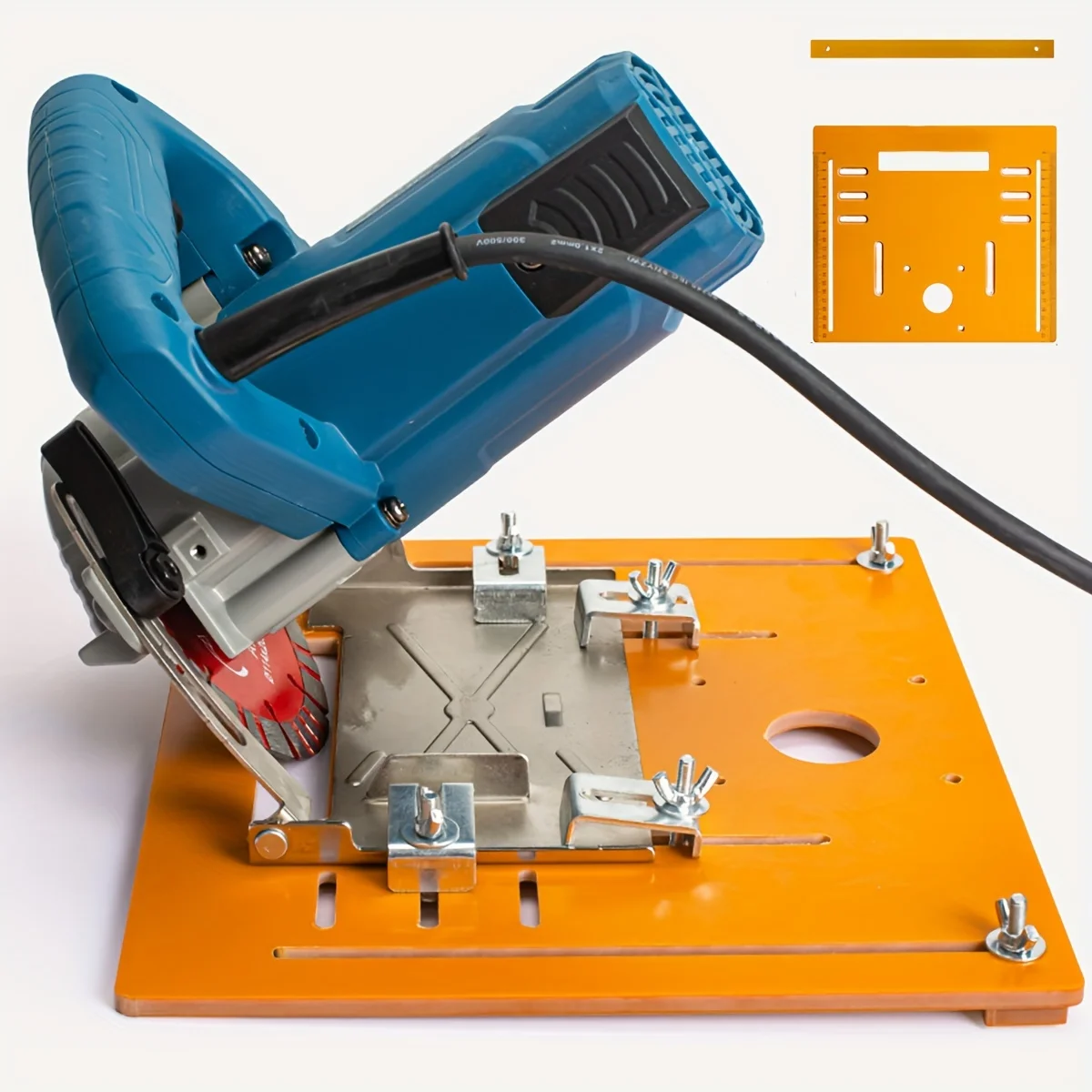

Cutting Machine Base Plate

Product Description

Secure, stabilize, and elevate your cutting setup with this Cutting Machine Base Plate — a reliable accessory designed to improve precision and reduce vibration for your most important cuts.

Key Features:

-

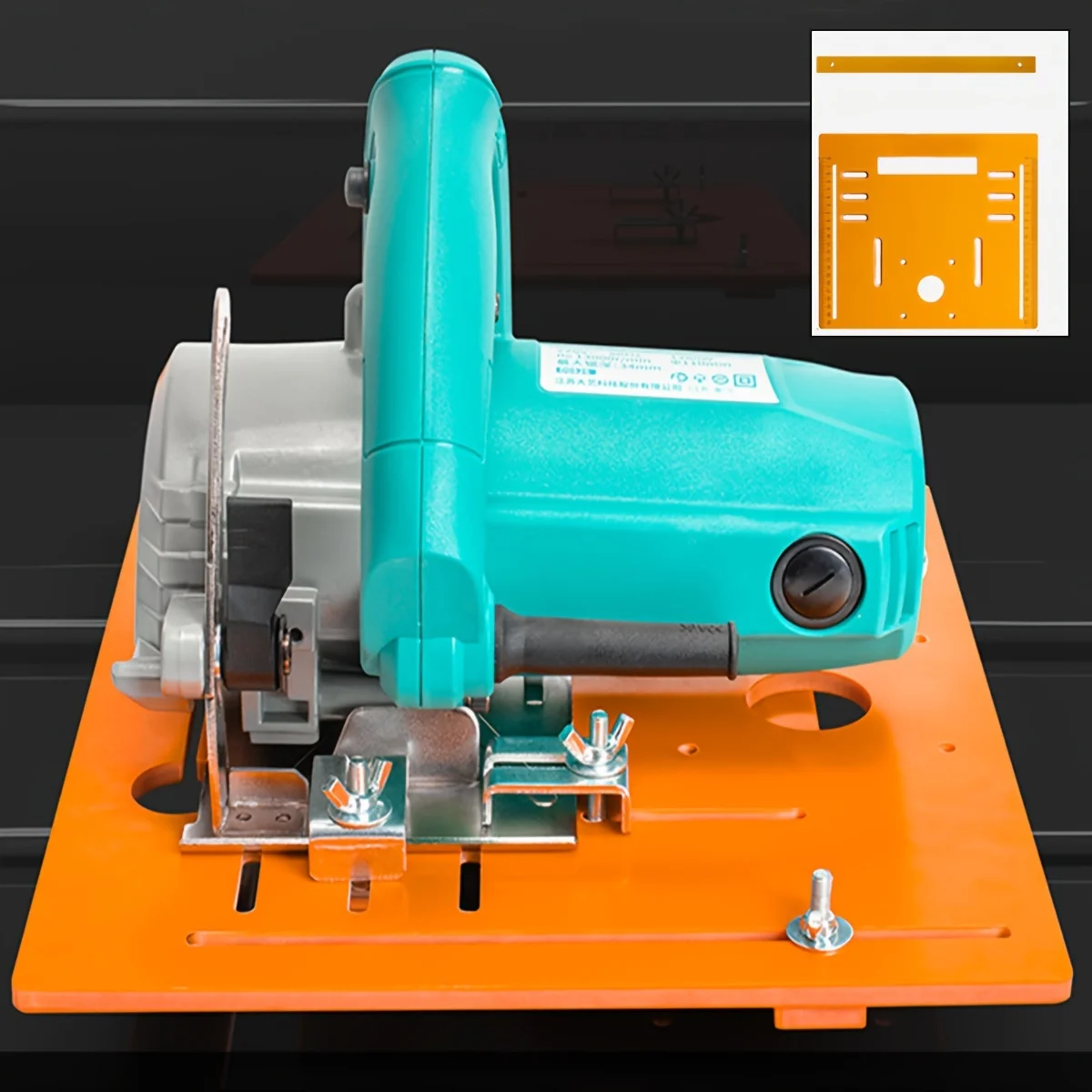

Stable Foundation: Provides a firm and flat surface for your cutting machine, ensuring smoother operation and minimizing wobble. kemperer+2ffmetro+2

-

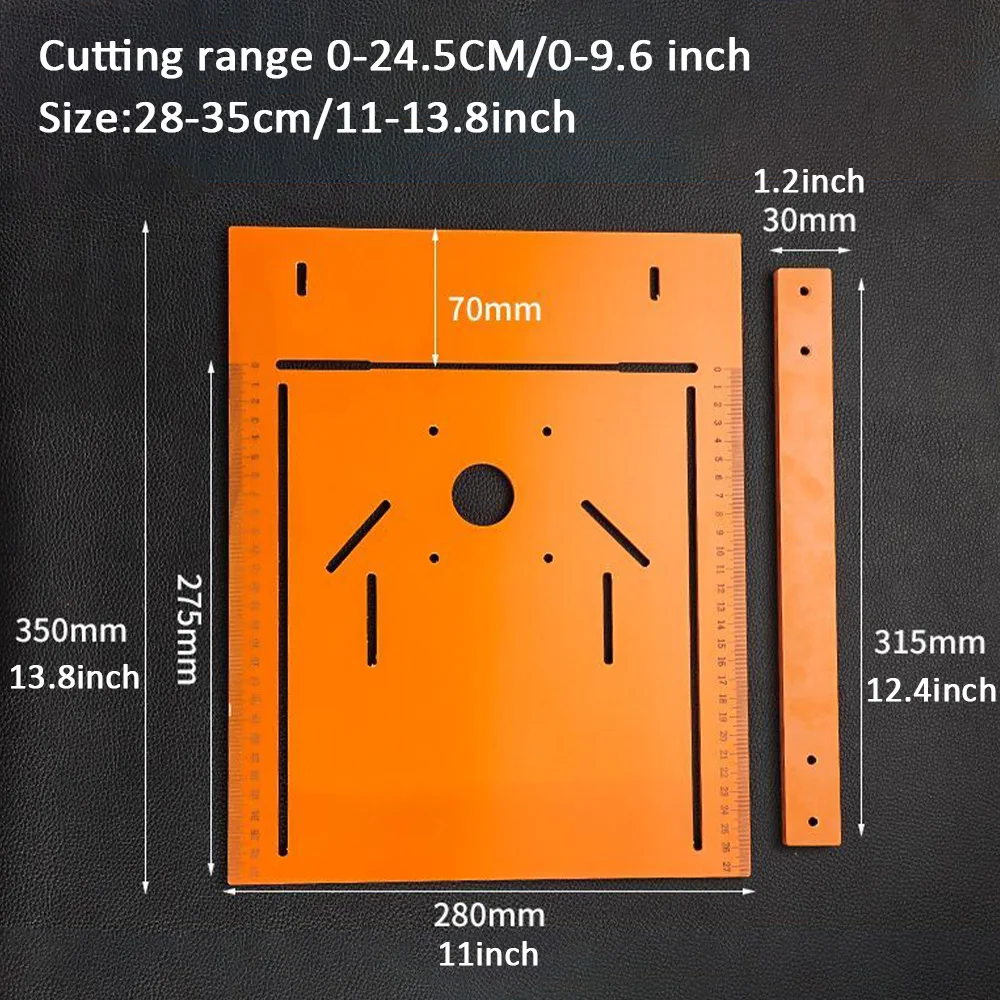

Built-in Measurement Scale: Includes a laser-etched or precision-marked scale, allowing for accurate positioning and repeatable cuts. colokik.com+1

-

Durable Material: Often made from heat-treated materials like bakelite or engineering plastic, which resist deformation and maintain a long service life. Kennve

-

Multi-Angle Cutting: Designed for both 90° flat cuts and 45° bevel cuts, giving you versatile functionality for various woodworking and fabrication tasks. kemperer

-

Universal Mounting: Comes with multiple hole positions to fit different saws and trimming machines — ideal for power tools used in stone work, woodworking, or CNC setups. colokik.com

-

Easy Adjustment: The punch-free design allows the base to be quickly secured, loosened, or removed, making it user-friendly and highly flexible. Kennve

Why You’ll Love It:

-

More control: A stable base ensures that your cuts are more accurate and consistent, letting you create smoother edges and tighter joints.

-

Better safety: Minimizing machine movement reduces the risk of kickback or misalignment during high-speed cutting.

-

Improved efficiency: With proper alignment and a reliable foundation, you'll spend less time redoing cuts and more time building.

-

Long-term value: Durable materials and quality construction mean the base plate won’t degrade after repeated use.

Pro Tips:

-

Make sure to fasten the base plate securely to both the workbench and your cutting machine to ensure optimal stability.

-

Regularly check and clean the scale markings to keep measurements precise.

-

If you're using different types of saws, test your setup first to find the best hole alignment for your specific tool.